Services

We are pleasant to interact with users to collect their tips and know-hows on equipment maintenance.

The module “Maintenance” here is intended to help users solve various problems they possibly encounter during equipment maintenance…

Indoor, no violent vibration and impact, conductive dust, explosive, corrosive strong gas, Suggestions on the independent room, put the position at the top of the equipment should not have water, want to have enough maintenance space: maintenance space set aside in front of the power supply is greater than the length of the power supply, maintenance, maintenance is convenient.

To ensure the normal operation of the host and the safe use of users, the host must be reliably grounded, and ensure that the ground cannot be connected with the zero line, the resistance of the ground line should be less than 4ω.

The size of externally connected copper bars (or copper wires) must absolutely ensure the safety of power transmission. The current density of A single copper bar with less than 2000A current should not exceed 2A/mm2, and that of A single copper bar with more than 2000A current should be 1.2-1.5A/mm2. If copper cables are used, the current density does not exceed 2.5A/MM2.

If not tinned, remove the oxidation layer on the surface and then connect the copper bar or cable. When cable connection is used, do not stack the two lugs together and then connect the busbar

in order to prevent debris from blocking the water pipe, it is recommended to add a filter at the water inlet (it can be considered to install it at the general water inlet). If the head of the water pump is too large and the inlet pressure exceeds the specified range, it is necessary to install the total pressure reducing valve to ensure that the pressure is within the prescribed range of cooling water.

If the user uses a hose, make sure the waterway is clear when bending. When connecting a hose, do not press the hose with a hose clamp. You are advised to cover the hose with yellow wax pipe to prevent hose damage caused by the hose clamp. For easy maintenance, inlet and outlet valves should be installed on each machine. Tap water can not be used, otherwise it is easy to cause water scale and blockage (after blockage, professional scale remover should be used for treatment)

Control signal line should avoid going together with power line, especially away from large electricity

When starting up, first turn on the water, and then turn on the power; When shutting down, turn off the power first, then cut off the water, in order to avoid the high temperature when starting up and shutting down the component damage.

When starting, first open the water valve, and then into the water valve; When shutting down, close the water inlet valve first, and then close the water outlet valve to avoid the water inlet pressure is too large to burst the pipe.

Operate according to the instructions of the control mode adopted by the product

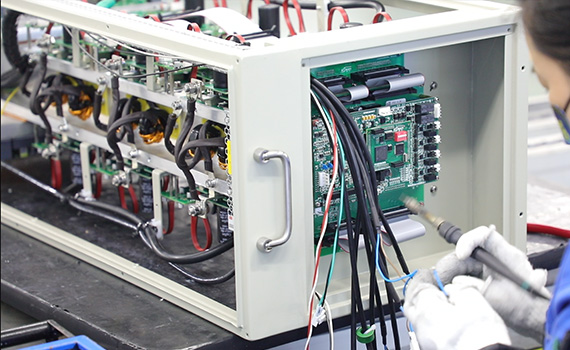

confirm the use temperature, humidity, dust, foreign matter, etc. Whether there is abnormal vibration and noise; Whether there is abnormal odor.

Whether the incoming cable is damaged; Check whether the fan works.

Check regularly every six months to see if the fastening part is loose; Whether the terminal connection is corroded or loose; Whether the heat dissipation air duct is blocked.

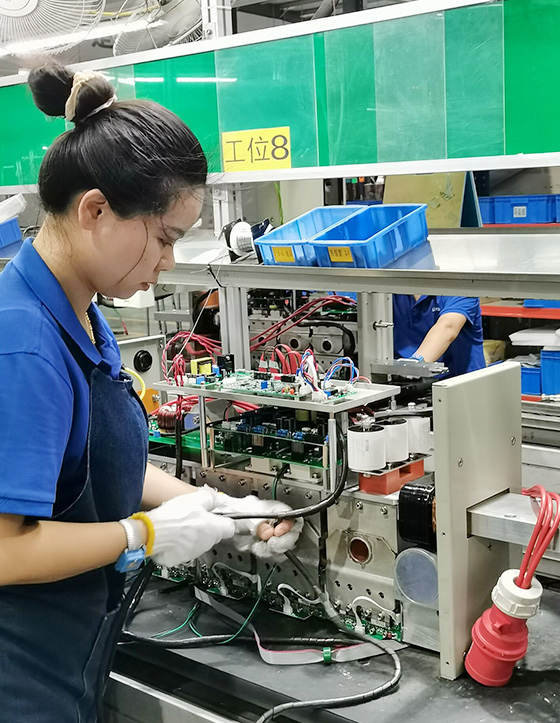

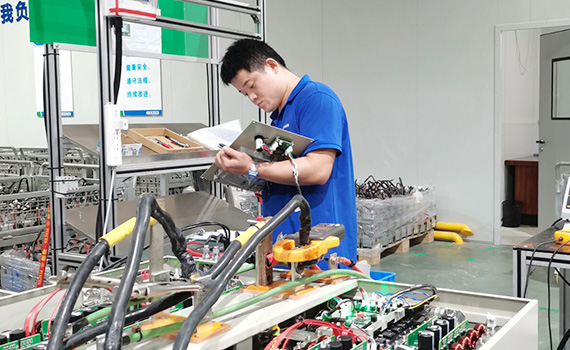

Liyuan Haina Rectifier, the professional manufacturer in IGBT and SCR rectifier, committed to providing you with quality solutions and products.

Get more details? We’ll response as soon as possible (within 12 hours).

Liyuan Haina Rectifier, the professional manufacturer in IGBT and SCR rectifier, committed to providing you with quality solutions and products.

Get more details? We’ll response as soon as possible (within 12 hours).