Input parameters: Three phase, AC380V±10% ,50HZ

Output parameters: DC 0~24V 0~2500A

Output mode: Common DC output

Cooling method: Water cooling

Power supply type: IGBT-based

Application Industry: Rear earth smelting and heating of the furnace body

Rare earth hydrometallurgy is a kind of chemical metallurgy. Most of the whole process is in solution and solvent. For example, the decomposition of rare earth concentrate, rare earth oxides, rare earth compounds and the separation and extraction of single rare earth metal are chemical separation processes such as precipitation, crystallization, REDOX, solvent extraction and ion exchange. At present, organic solvent extraction is widely used, which is a common process for industrial separation of high purity single rare earth elements. Hydrometallurgy process is complex, product purity is high, the method of production of finished products wide application.

Pyrometallurgical process is simple and has high productivity. Rare earth pyrometallurgy mainly includes silicon thermal reduction method to obtain rare earth alloy, molten salt electrolysis method to obtain rare earth metal or alloy, metal thermal reduction method to obtain rare earth alloy. The common characteristic of pyrometallurgy is production under high temperature.

In industrial mass production of mixed rare earth metals, molten salt electrolysis is generally used. The process involves heating and melting rare earth compounds, such as rare earth chlorides, and then electrolysis to precipitate rare earth metals on the cathode. There are two electrolysis methods: chloride electrolysis and oxide electrolysis. Methods for preparing single rare earth metals vary from element to element. Because of high vapor pressure, samarium, europium, ytterbium and thulium are not suitable for electrolysis, but reduction distillation is used. Other elements can be prepared by electrolysis or metal thermal reduction.

Characteristic Types |

Parameter Items |

Technical Requirements |

| Power Types | Power types | High-frequency Power Supply |

| Model and specifications | TBSB-2500A/24V | |

| Cooling mode | Water-cooled | |

| Switch tube type | IGBT | |

| Input Characteristics | Rated Input Voltage | Three-phase, AC380V±10% ,50HZ |

| Rated Input Power | 67.2 KW | |

| Rated Input Current | AC 102A | |

| Input Power Factor | COSΦ≥0.95 | |

| Output Characteristics | Output Voltage | DC 0~24V |

| Output Current | DC 0~2500A | |

| Stabilized Current Precision | ≤1%(Rated Current) | |

| According to accuracy | 1A,0.1V | |

| Rated output efficiency | ≥94% | |

| Environmental Conditions | Installation site | Indoor installations |

| Altitude | ≤2000 meters | |

| Ambient temperature | -20℃~40℃ | |

| Relative humidity | ≤94% | |

| Control Mode | Operating mode | PLC, ADDA, Ethernet, RS485 and RS232 |

| External Dimension | Height*Width*Depth | H185mm×W402mm×D650mm |

| Protection Characteristics | With over voltage, over current, overload, short circuit, overheating and other abnormal self-protection function | |

| Application | Model | Output Parameters |

| Furnace body heating | ACF-2000A/35V | 35Vdc/2000A |

| ACF-3000A/24V | 24Vdc/3000A | |

| ACF-4000A/36V | 36Vdc/4000A | |

| TDSB-5000A/45V | 45Vdc/5000A | |

| TDSB-6000A/45V | 45Vdc/6000A | |

| TDSB-10000A/45V | 45Vdc/10000A | |

| TBSB-6000A/24V | 24Vdc/6000A | |

| TBSB-15KA/45V | 45Vdc/15KA | |

| Smelting | TBSB-5000A/12V | 12Vdc/5000A |

| TBSB-6000A/12V | 12Vdc/6000A | |

| TBSB-8000A/12V | 12Vdc/8000A | |

| TBSB-10000A/12V | 12Vdc/10000A | |

| TBSB-12000A/12V | 12Vdc/12000A | |

| TBSB-15000A/12V | 12Vdc/15000A | |

| TBSB-6000A/15V | 15Vdc/6000A | |

| TBSB-8000A/15V | 15Vdc/8000A | |

| TBSB-10000A/15V | 15Vdc/10000A | |

| TBSB-12000A/15V | 15Vdc/12000A | |

| TBSB-15000A/15V | 15Vdc/15000A | |

| TBSB-16000A/14V | 14Vdc/16000A | |

| TBSB-15000A/11V | 11Vdc/15000A | |

| TBSB-18000A/11V | 11Vdc/18000A | |

| TBSB-8000A/13V | 13Vdc/8000A |

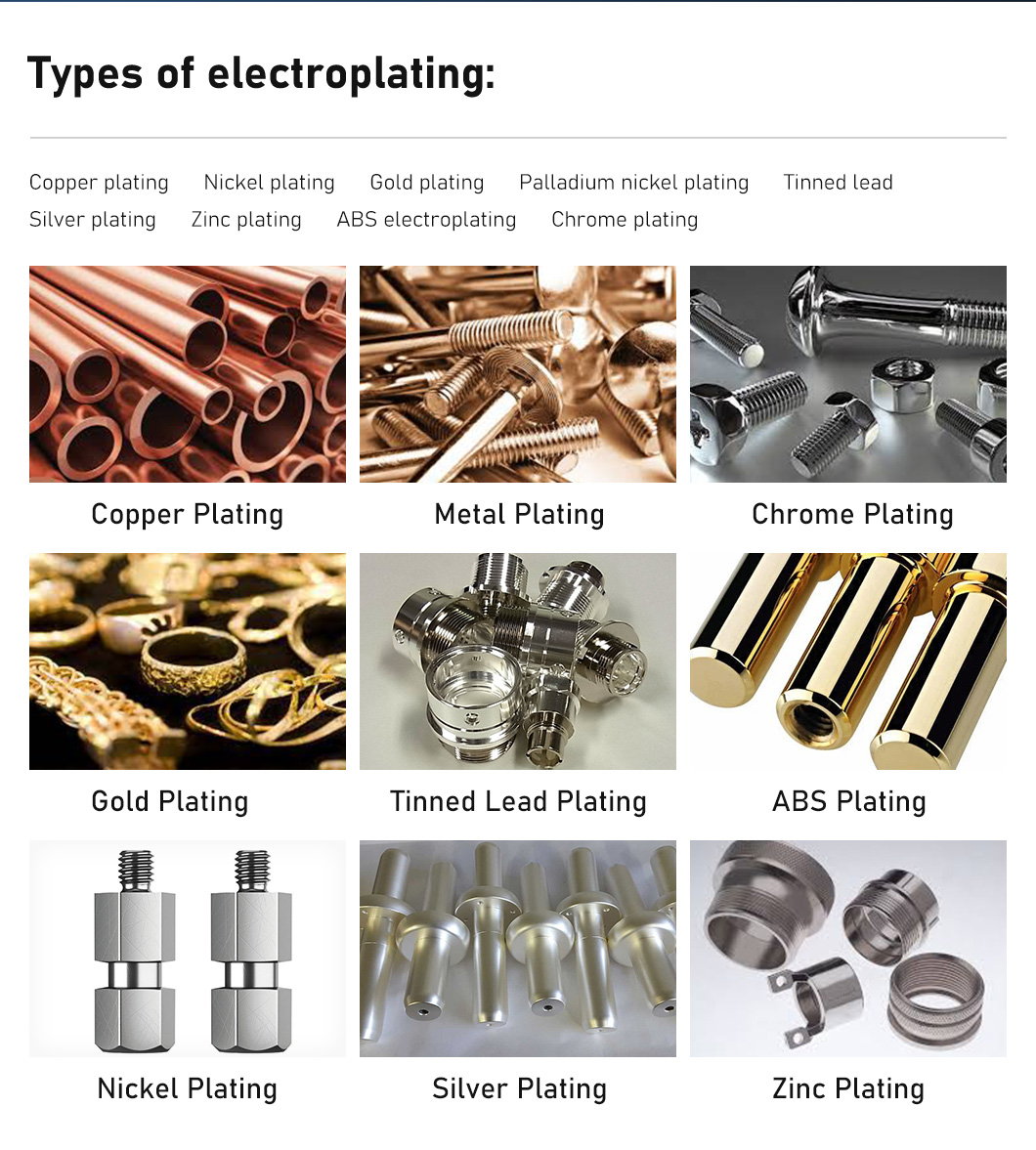

If you need other rectifier for electroplating, we can custom design them according to customer requirements. Please contact us.

Seeking 24V 2500A IGBT high power rectifier for electroplating? Liyuan Haina Group, a professional manufacturer with 27+ years specializing in industrial rectifiers, supplies global clients including the United States, Canada, Britain, Italy, Spain, South Africa, Russia, the UAE, Japan, South Korea, Malaysia, etc. Our advanced factory delivers cost-effective Made-in-China solutions, with competitive prices and customizable options. Contact us for sales inquiries.

Hot Tags: 24V 2500A IGBT High Power Rectifier for Electroplating, Electroplating Rectifier, price, high efficiency, High reliability, China, manufacturers

Liyuan Haina Rectifier, the professional manufacturer in IGBT and SCR rectifier, committed to providing you with quality solutions and products.

Get more details? We’ll response as soon as possible (within 12 hours).

Liyuan Haina Rectifier, the professional manufacturer in IGBT and SCR rectifier, committed to providing you with quality solutions and products.

Get more details? We’ll response as soon as possible (within 12 hours).