Input parameters: Single phase, AC220V±10% ,50HZ

Output parameters: DC 0~9V 0~100A

Output mode: Common DC output

Cooling method: Air cooling

Power supply type: IGBT-based high frequency power supply

Application Industry: Plating industry

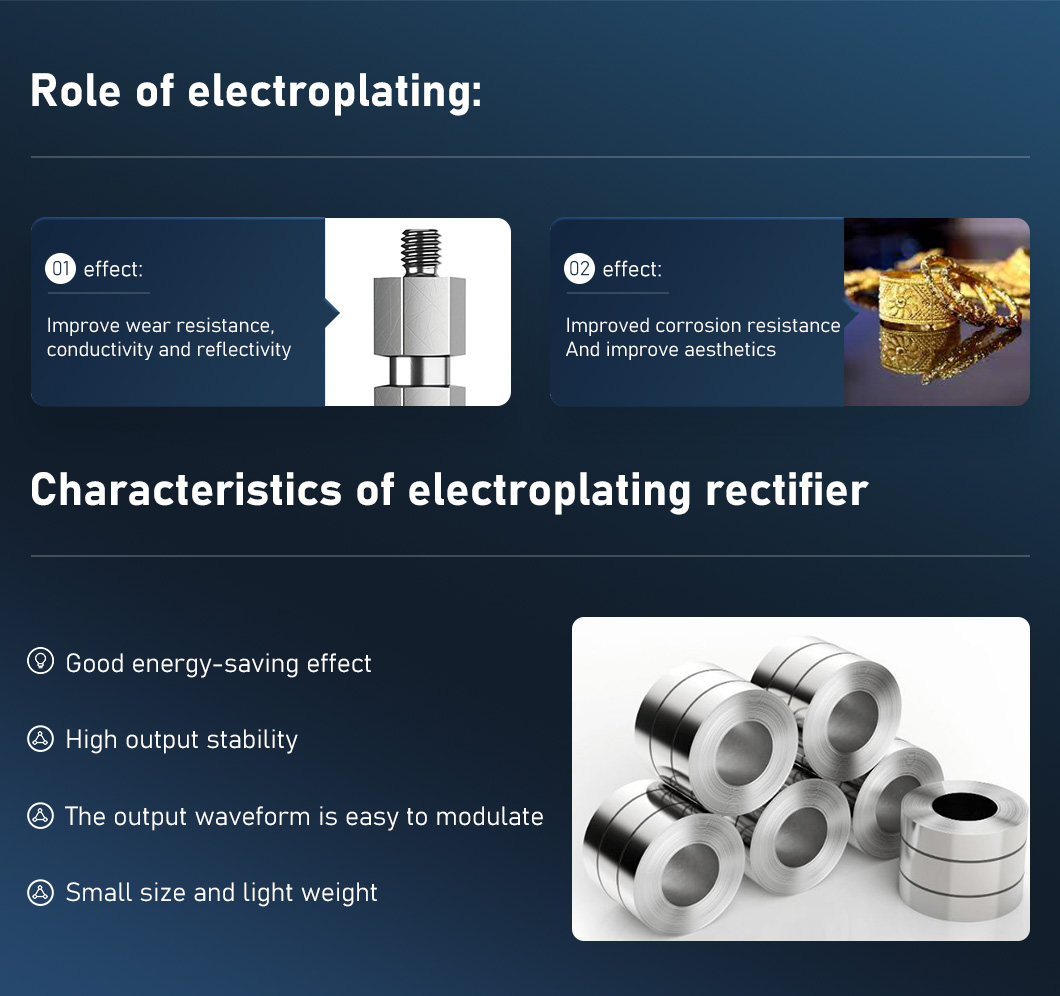

In an 9V 100A electroplating rectifier power supply, after the AC input voltage is filtered by a rectifier circuit, high-voltage DC power is obtained. The “variable frequency conversion” stage inverts this high-voltage direct current into approximately 30kHz high-frequency alternating current. This high-frequency AC is then transformed into secondary voltage via a high-frequency transformer and filtered through a high-frequency rectifier circuit to produce the required output voltage. The electroplating rectifier employs a control circuit to sample output voltage and current. These sampled signals undergo closed-loop feedback to generate pulse width modulation (PWM) signals, which regulate the inverter circuit and maintain stable output voltage/current – a critical requirement for precision electroplating applications.

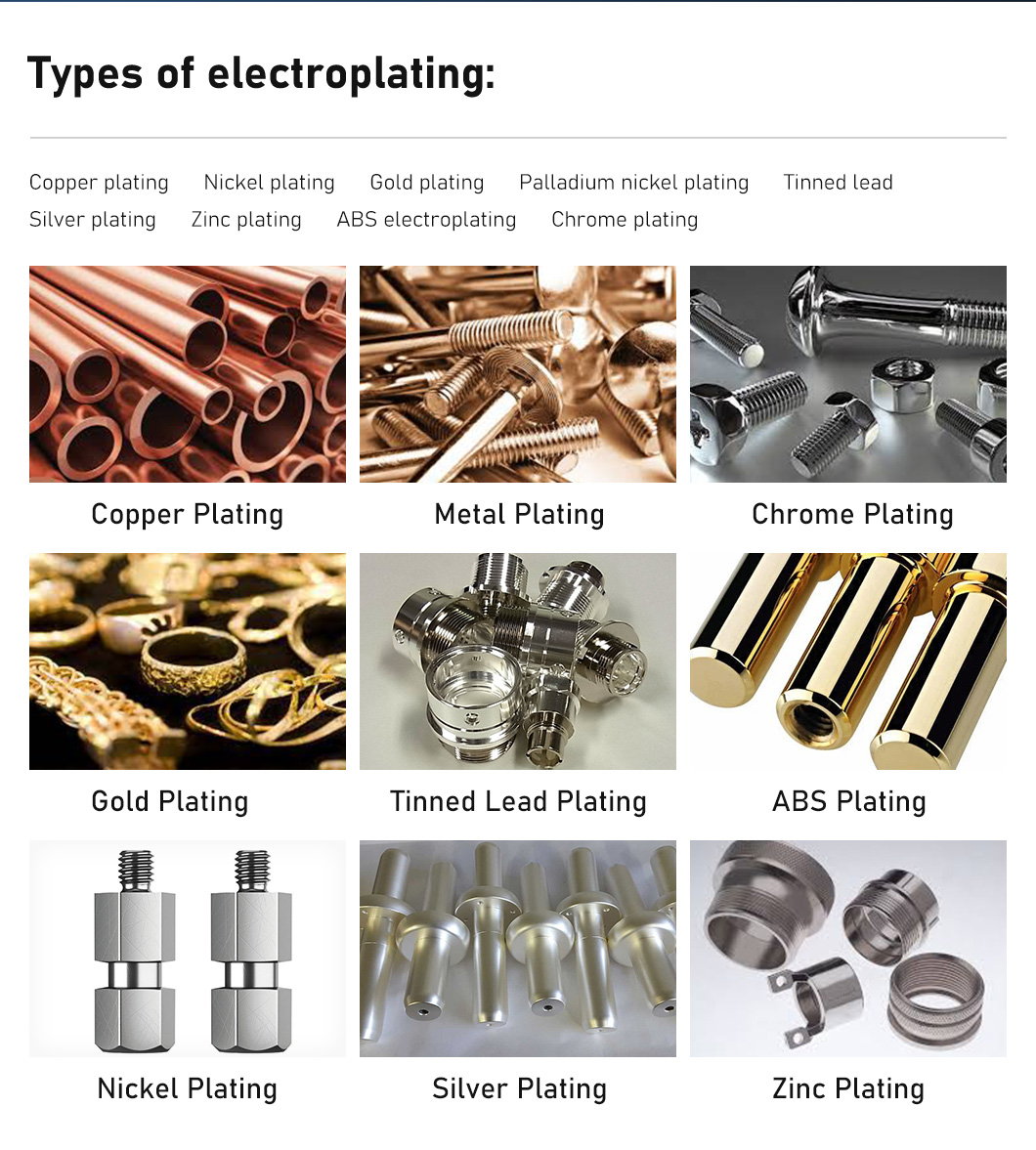

Types of plating

Elements of electroplating

Characteristic Types |

Parameter Items |

Technical Requirements |

| Power Types | Power types | High-frequency Power Supply |

| Model and specifications | HIFB-100A/9V | |

| Cooling mode | Air-cooled | |

| Switch tube type | IGBT | |

| Input Characteristics | Rated Input Voltage | Single phase, AC220V±10% ,50HZ |

| Rated Input Power | 1.0KW | |

| Rated Input Current | AC 4.5A | |

| Input Power Factor | COSΦ≥0.95 | |

| Output Characteristics | Output Voltage | DC 0~9V |

| Output Current | DC 0~100A | |

| Stabilized Current Precision | ≤1%(Rated Current) | |

| According to accuracy | 0.1A,0.01V | |

| Rated Output efficiency | ≥91% | |

| Environmental Conditions | Installation site | Indoor installations |

| Altitude | ≤2000 meters | |

| Ambient temperature | -20℃~40℃ | |

| Relative humidity | ≤90% | |

| Control Mode | Operating mode | PLC, ADDA, Ethernet, RS485 and RS232 |

| Weight | Net weight | About 32KG |

| External Dimension | Height*Width*Depth | H188mm×W323mm×D454mm |

| Protection Characteristics | With over voltage, over current, overload, short circuit, overheating and other abnormal self-protection function | |

| Application | Model | Output Parameters |

| 220V Single phase input | TBFB-50A9V | 9Vdc/50A |

| HMFB-5A12V | 12Vdc/5A | |

| TBFBZ-10A12V | 12Vdc/10A | |

| HMFB-20A12V | 12Vdc/20A | |

| HMFB-150A12V | 12Vdc/150A | |

| TBFA-30A12V | ±12Vdc/30A | |

| HMFB-30A12V | 12Vdc/30A | |

| HMFB-50A12V | 12Vdc/50A | |

| HMFB-100A12V | 12Vdc/100A | |

| HMFB-150A12V | 12Vdc/150A | |

| TBFBZ-2200A12V | 12Vdc/2200A | |

| HMFB-20A15V | 15Vdc/20A | |

| HMFB-100A15V | 15Vdc/100A | |

| HMFB-50A20V | 20Vdc/50A |

If you need other power electroplating rectifiers, we can custom design them according to customer requirements. Please contact us.

Seeking 9V 100A electroplating rectifier power supply? Liyuan Haina Rectifier, a professional manufacturer with 27+ years specializing in industrial rectifiers, supplies global clients including the United States, Canada, Britain, Italy, Spain, South Africa, Russia, the UAE, Japan, South Korea, Malaysia, etc. Our advanced factory delivers cost-effective Made-in-China solutions, with competitive prices and customizable options. Contact us for sales inquiries.

Hot Tags: 9V 100A Electroplating Rectifier Power Supply, Surface Finishing, igbt electroplating rectifier, electroplating rectifiers, DC power supply, Price, sale, manufacturer, China

Liyuan Haina Rectifier, the professional manufacturer in IGBT and SCR rectifier, committed to providing you with quality solutions and products.

Get more details? We’ll response as soon as possible (within 12 hours).

Liyuan Haina Rectifier, the professional manufacturer in IGBT and SCR rectifier, committed to providing you with quality solutions and products.

Get more details? We’ll response as soon as possible (within 12 hours).