Input parameters: Three-phase AC 380V ± 10%, 50Hz

Output voltage: DC 0~80V

Output current: DC 0~1000A

Cooling method: Air cooling

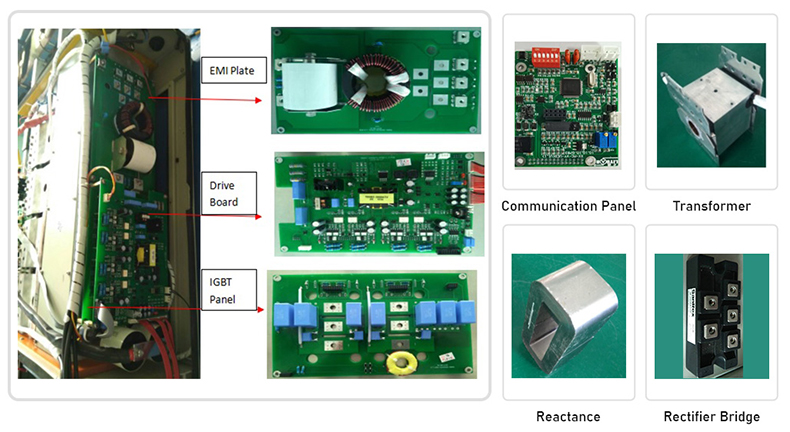

Power supply type: IGBT-based power supply

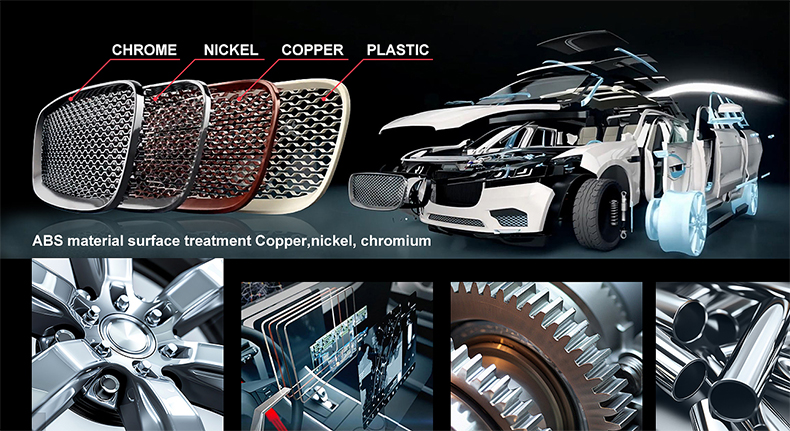

Application Industry: Copper, nickel, zinc, chrome, gold, and silver plating, PCB and electronic components, automotive parts, and precision or aerospace components.

Coating technologies are widely used to improve corrosion resistance, durability, and surface performance of metal components. Among them, E-Coating, CED coating, and PVD coating represent three of the most commonly adopted processes in modern industrial surface treatment.

The electroplating coating rectifier is a DC power supply used in industrial plating lines. It keeps current stable over long working hours. That stability is crucial for uniform coating and smooth surfaces.

You’ll find it in metal finishing workshops, automated plating lines, and custom surface treatment setups.

AC power first goes through a three-phase transformer. Then it’s converted to DC using silicon diodes. This simple setup works reliably for most standard plating processes. Maintenance is easy, and performance is steady.

SCR (thyristor) rectifiers handle higher current jobs. Adjusting the firing angle changes output current and voltage. This helps when the plating process has multiple stages.

High-frequency switching rectifiers are common on modern automated lines. They use high-frequency switching to convert and isolate power. The output is stable with low ripple, while the units are smaller, lighter, and more efficient than older models.

Manufacturers widely use high-frequency rectifiers for surface treatment and electroplating applications, including copper, nickel, zinc, chrome, gold, and silver plating on PCBs, electronic components, automotive parts, precision or aerospace components. These rectifiers offer energy-efficient operation, low ripple for improved coating consistency, compact design to save workshop space, and built-in controls for automated processes.

1)Field application diagram:

2)Industry application examples:

› Steady DC output, keeps coating uniform.

› Current and voltage can be changed to suit the process.

› Works in constant current, constant voltage, or multi-stage modes.

› Made for nonstop operation, the components are robust and reliable.

› Small and easy to install, with maintenance kept to a minimum.

› Can connect to PLCs or computer control.

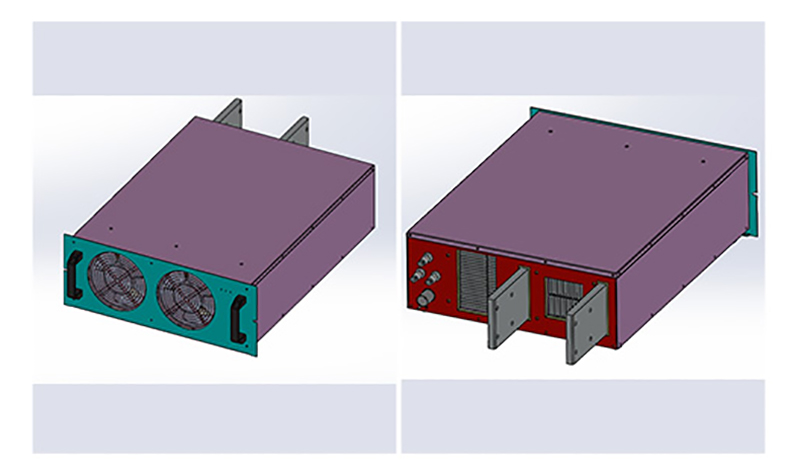

Air Cooling:Heat dissipation fan + air duct + comb heat sin

Water Cooling:Built-in water circulation line

| Attribute type | Parameter items | Technical requirements | |

| Input characteristics | Rated input voltage | Three-phase AC 380V ± 10% 50Hz

In line with the national power quality standards |

|

| Rated input current | AC 141A | ||

| Rated input power | 92.5VA | ||

| Rated input power factor | COSΦ≥0.95 | ||

| Output characteristics | Output voltage | DC 0~80V adjustable | |

| Output current | DC 0~1000A adjustable | ||

| Steady current precision | ≤1% | ||

| Steady voltage precision | ≤1% | ||

| Display accuracy | 1A,0.1V | ||

| Rated output efficiency | ≥91% | ||

| Insulation characteristics | Insulation resistance | Input-output: ≥ 5MΩ | |

| Input-chassis: ≥ 5MΩ | |||

| Output-chassis; ≥5MΩ | |||

| Protection characteristics | It has self-protection function under abnormal conditions such as overvoltage, overcurrent, overload, short circuit and overheat | ||

| Other characteristics | Noise | ≤75dB | |

| Operating status | Continuous full load operation of the product | ||

| Load grade | Grade II | ||

| Insulation grade of transformer | Class B | ||

| Weight | 500kg | ||

» Solution

Liyuan will keep up with the world’s latest technology closely, and uphold the concept of providing customers with high-quality power supplies and professional integrated services.

With advanced design and rich experience in rectifier manufacturing, we will provide the best power solutions as well as the most stable and efficient power supply for users both at home and abroad.

» Technical Capability

LIYUAN rectifier is the most competitive brand in China

Company relies on strong technology research and development cooperation basis, created a number of advanced technology, in recent 3 years amounted to more than 30 to apply for a patent, which has nearly 10 patents of invention.

Equipped with the national electric power transformation and control engineering technology research center (branch), and has set up a loan enterprise academician workstation.

Strict implementation of ISO quality management system, and through the CE safety certification, has been implementing ERP management for many years, to achieve the network, systematic computer control, the formation of a standard, efficient modern management system.

» Qualification certification

Liyuan adhere to innovation and the continuous improvement of power conversion efficiency and product quality.

The increasing R&D investment every year, and cooperation with China’s well-known universities, we has established the research center of national electric power conversion and control engineering technology.

Especially the related core patents of high-power synchronous rectifier power supply, stay ahead of the whole industry in China.

The ISO 9001 quality management system has been fully implemented in Liyuan, including quality inspection of components in warehouse, production process inspection, and final product inspection.

We adopt advanced scientific quality management system and the most stringent testing methods in the whole process to ensure the stability and reliability of products.

» Service

› Packing

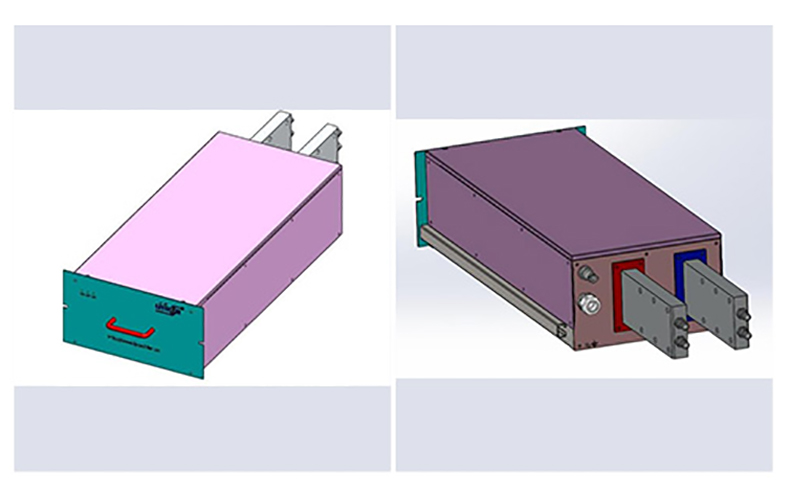

1)Small size rectifier packing in carton box separately.

2)Large size rectifier will be packed in wooden case.

3)We guarantee that all the packing is intact when it reaches its destination.

› Shipping

1)30-45 Days after payment.

2)Transport: DHL, FEDEX, UPS, Air shipping, Boat shipping

3)You may choose our shipping partner or your own partner.

› Maintenance

We are pleasant to share our theory and experience on equipment maintenance with users.

We are pleasant to interact with users to collect their tips and know-hows on equipment maintenance.

The module “Maintenance” here is intended to help users solve various problems they possibly encounter during equipment maintenance…

If you need other coating rectifiers, we can custom design them according to customer requirements. Please contact us.

Looking for a low ripple 1000A 80V DC rectifier for industrial coating applications? Liyuan Haina Rectifier Group is one of the professional manufacturers and suppliers in this field. With over 27 years of focus on R&D, design, production, sales, and technical services for industrial rectifiers, we have already exported our products to the United States, Canada, Britain, Portugal, Italy,Thailand, Spain, South Africa, Russia, the UAE, Japan, South Korea, Malaysia, and other parts of the world. Equipped with a productive factory, we warmly welcome you to purchase our high-quality, Made-in-China products at competitive prices or try our customized service.

Hot Tags: Low Ripple 1000A 80V DC Rectifier for Industrial Coating Applications, Electrophoretic Coating Rectifier, CED Coating Rectifier, Rectifier for PVD Coating, Electroplating Coating Rectifier, surface treatment industry, price, China

Liyuan Haina Rectifier, the professional manufacturer in IGBT and SCR rectifier, committed to providing you with quality solutions and products.

Get more details? We’ll response as soon as possible (within 12 hours).

Liyuan Haina Rectifier, the professional manufacturer in IGBT and SCR rectifier, committed to providing you with quality solutions and products.

Get more details? We’ll response as soon as possible (within 12 hours).