Advantages: simple control and high precision, only two-core shielded wire communication, simple wiring, digital transmission, high transmission precision, strong anti-interference capability, self-correcting function and multiple data retransmission function, strong interference capability, no signal attenuation, long communication distance, up to 1.2km.

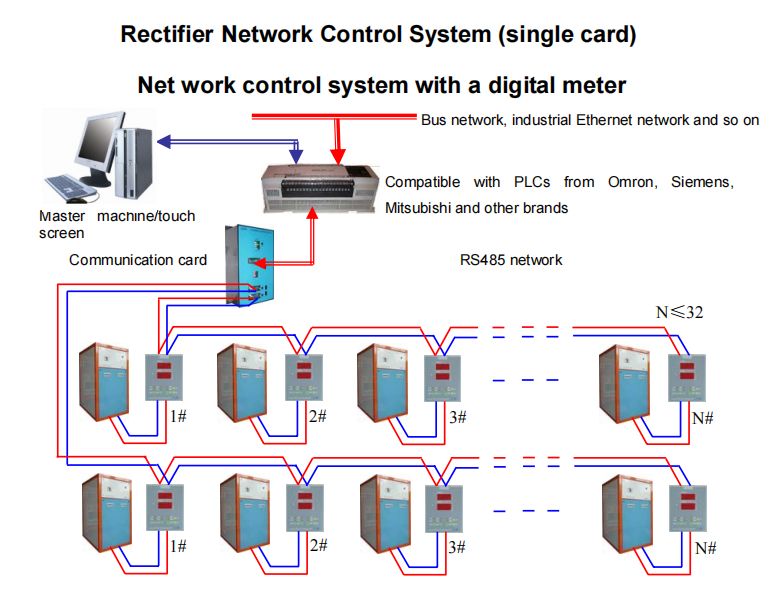

Liyuan Rectifier RS 485 Network Control System is a digital, effective, rapid and stable communication system. It consists of a master machine, PLC, LY-RS232/RS485 and a slave machine (a rectifier equipped with a network control card RS485.

1. Withdigital data transfer, the correctness is ensured.

2.The status word and control word of the rectifier are read and written in relevant Area-VW of the PLC (Users can change it in PLC.)

3.Amonitoring cycle for all 64 rectifiers with RS485 control card is about 4 seconds.

4.The rectifier can automatically integrate with the system, simplifying the control of rectifiers. Itis possible to use ≥0.5 mm2 2-core STP or a special PROFIBUS cord to connect 32 rectifiers in a parallel manner.

5.In case the PLC is disconnected with the power supply,the rectifier will be turned off automatically.

6.In case the PLC fails to communicate with the rectifier, the rectifier will be turned off after 2 minutes.

1.Firstly,divide relevant Area-VW in the master machine PLC, this Area-VW includes: ①commands for the rectifier; set the current/voltage values; ② error codes, status parameters and actual current/voltage values of rectifiers. Each rectifier needs 6 Area-VW, namely, command used to turn on/off the rectifier and stabilize the voltage/current, set current/voltage value, communication error code, actual status word, actual current value and actual voltage value. After connecting the Communication Port- RS232 of the PLC with the human-machine interface of its master machine, the value in Area-VW can be displayed; it is also possible to use the human-machine interface of the master machine to input parameters into the Area-VW. Meanwhile, it is possible to connect the Port- RS 232 of the PLC with communication card LY-RS232/RS485PROTX. During the course of communication, the PLC is a receiver; the communication card reads data from or writes data into the PLC. Therefore, the PLC doesn’t need any communication programs except setting the status and mode of its ports. Please refer to the instruction hereinafter.

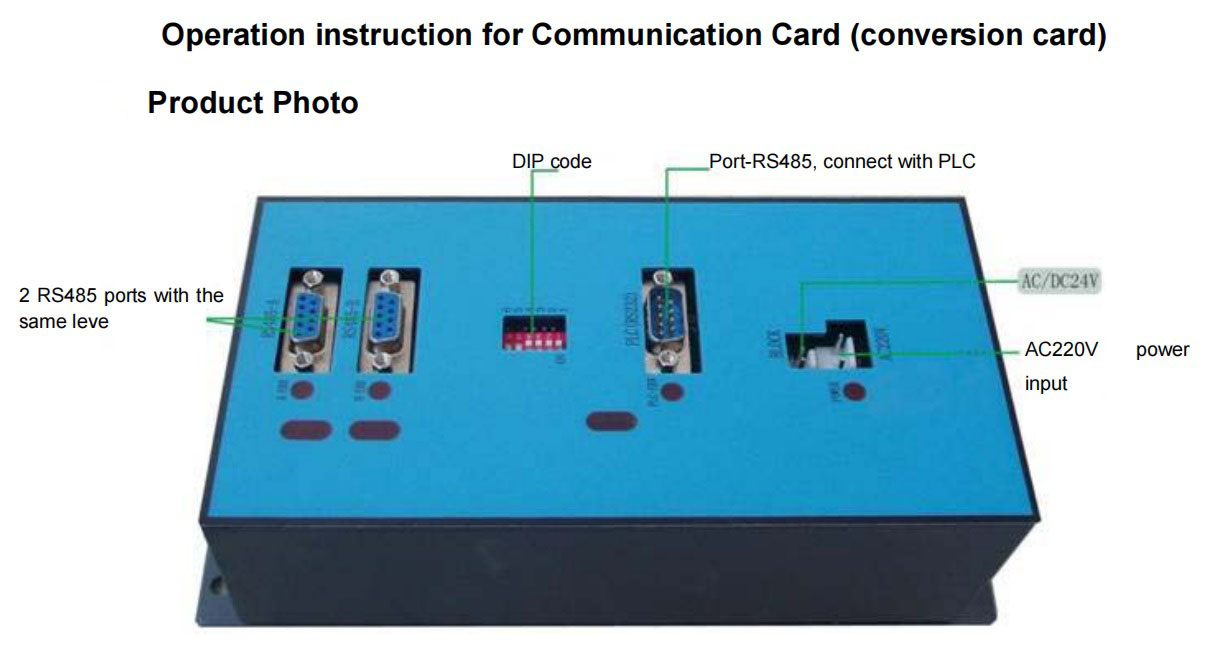

2.Thedata of RS485 is converted by Communication card LY RS232/RS485PROTX. The communication card automatically writes (WD) the status words and actual current/voltage of the rectifier into relevant Area-VW of PLC (according to previous setting which can be changed later) through Port-RS232 of the PLC; or the communication card automatically read (RD) the data in relevant Area-VW of the PLC and then transfers them to the rectifier. The card is equipped with 2 Port- RS485 of the same level. Each port can be connected with 32 rectifier equipped with LY-RS485 control card. There is also a RS232 card which can be directly connected with the Port-RS232 of PLC or a Port- RS232 converted from a programming port by an adapter.

3.Therectifiers equipped with control card are used as slave They are completely in RS485 communication mode. Each rectifier confirms its communication address by the DIP switch. They receive their own commands from the master machine and keep their own status readable by the master machine.

1.Rectifierwith RS 485 control card: It is possible to use ≥0.5 mm2 2-core STP or a special PROFIBUS cord to connect 32 rectifiers in a parallel manner. Install a 220 ohm terminal resistance in the last rectifier. Each rectifier uses a different address code. Connect with Prot RS485A or Port-RS485B of communication card LY-RS232/RS485.

2.ConnectPort RS232 of communication card LY-RS232/RS485PROTX to Port-RS232C of the PLC or Port-RS232 converted from a programming port by an adapter.

3.Connectthe power cord (supplied together with the device).

4.Use an output of the PLC as a normally-closed output and connect it with the operationterminal of communication card LY-RS485/RS232, controlling the operation of the whole system.

5.Connectwith the power supply and the system will automatically communicate and transfer data. Different data areas of the PLC will control and display rectifiers with different address.

Hot Tags:Network control system single card,dc power supply for electrolysis,Rectifier Network Control System,igbt plating rectifier,plating rectifier manufacturers China,factory,sale,price

Liyuan Haina Rectifier, the professional manufacturer in IGBT and SCR rectifier, committed to providing you with quality solutions and products.

Get more details? We’ll response as soon as possible (within 12 hours).

Liyuan Haina Rectifier, the professional manufacturer in IGBT and SCR rectifier, committed to providing you with quality solutions and products.

Get more details? We’ll response as soon as possible (within 12 hours).