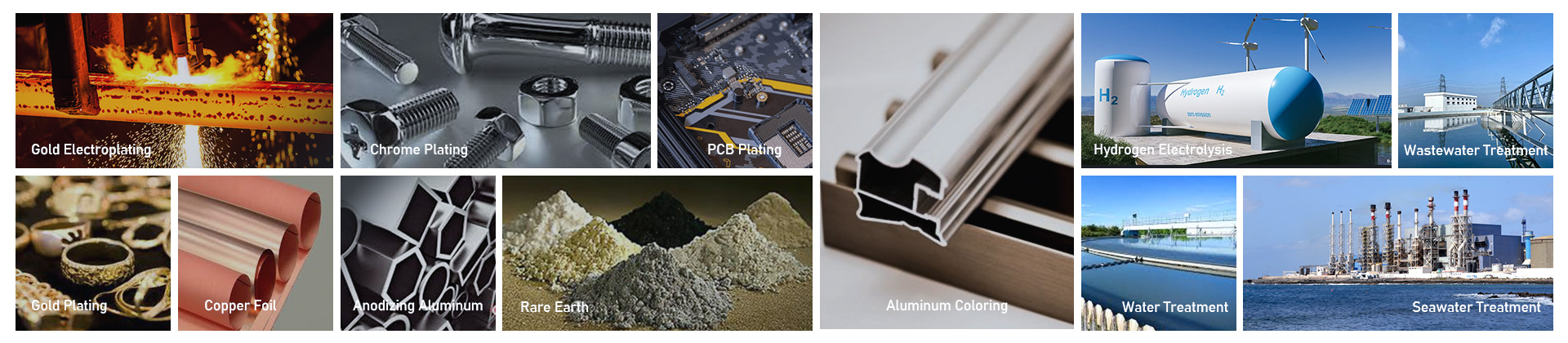

Application

Serbia 300V/48KA Copper Electrolysis Project

The 300V/48KA copper electrolysis project in Serbia, using silicon controlled electrolytic rectifiers. Liyuan's technical team went to the site for installation and commissioning to help the customer solve the technical problems in the actual application and ensure the normal use and stable operation of the project. Below are the pictures of the technicians' on-site commissioning and the actual photo of the customer's copper electrolysis project.

Liyuan rectifier, taking the lead in IGBT rectifier and SCR rectifier in China.

Get more details? We’ll respond as soon as possible (within 24 hours).

Liyuan rectifier, taking the lead in IGBT rectifier and SCR rectifier in China.

Get more details? We’ll respond as soon as possible (within 24 hours).